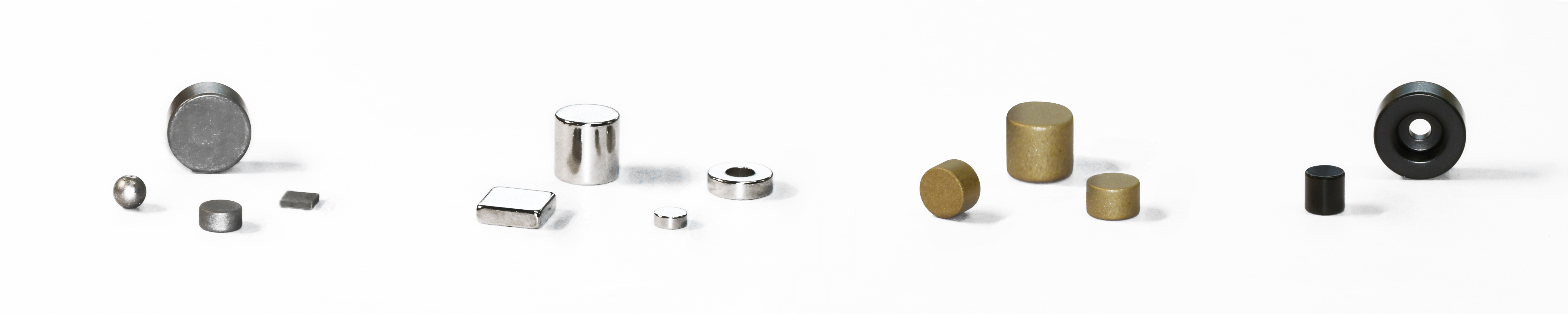

Types of possible coatings

| Coating | Colour | Characteristic | ||

|---|---|---|---|---|

| Zn (Zinc) |

bright blue | Regular protection | ||

| Ni-Cu-Ni (Nickel-Copper-Nickel) |

bright silver | Excellent humidity, heat and salt spray resistance. | ||

| Ni-Cu-Ni + Epoxy ( Nickel-Copper-Nickel + Epoxy) |

grey or black | Excellent humidity, heat and salt spray resistance. Very good abrasion resistance. Process-related small contact dots may remain on the magnet. | ||

| Ni-Cu-Ni + Au ( Nickel-Copper-Nickel + Gold) |

golden | Excellent humidity, heat and salt spray resistance with superior apperance and decoration. | ||

| Schwarz Ni ( Black Nickel) |

bright black | Excellent humidity, heat and salt spray resistance. | ||

| Teflon ( PTFE) |

yellow / black | High temperature and rub resistance. Self-lubricant and 100% water-proof. | ||

| Parylene ( Polymer) |

transparent | Excellent humidity, salt spray, corrosive vapors, and solvents resistance. Free of pore but low abrasion resistance. | ||

| Phosphatiert | dark grey | Temporary protection. |

Remarks:

- SST (Salt Spray Test) at 35°C / 5% NaCI (Sodium chloride).

- Not all coatings can be used on all magnet material.

- Other coatings available on request.

Tags

Coatings

Nickel

Epoxy

Parylene

Appearance

Gold

PTFE