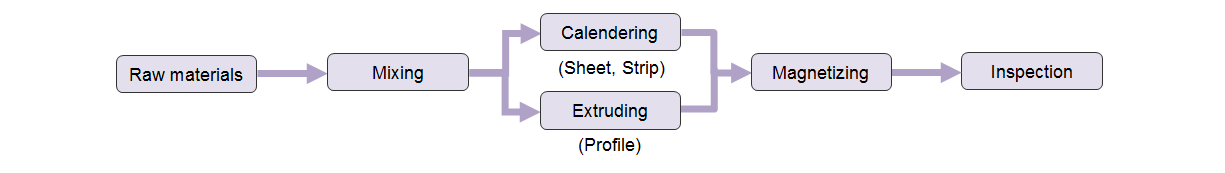

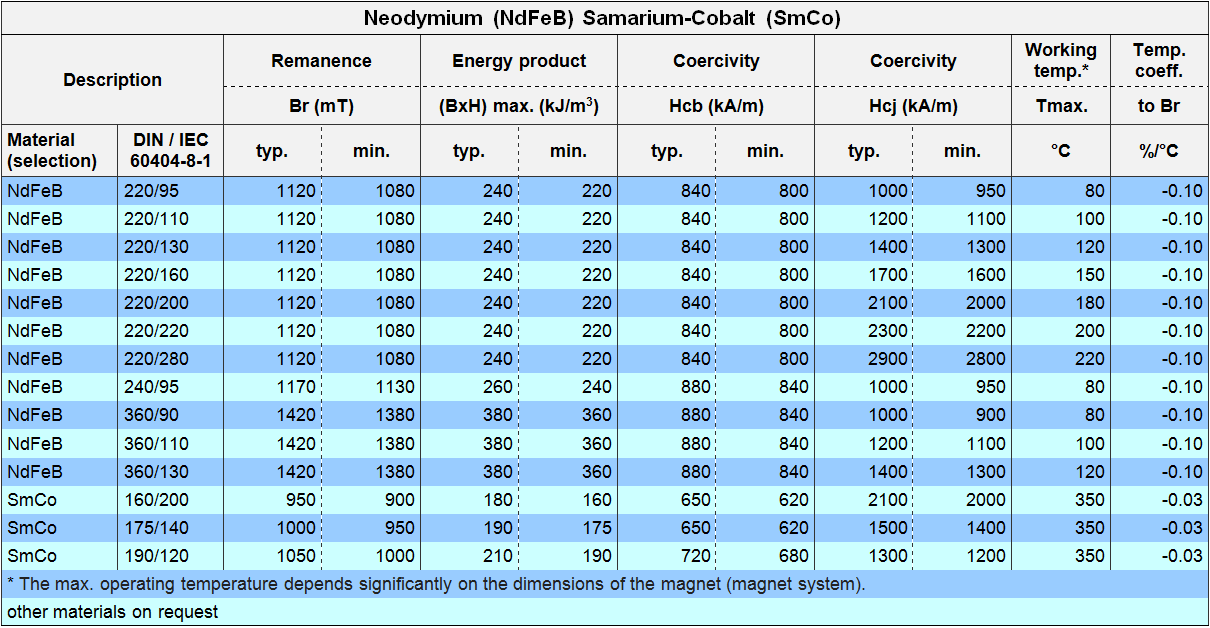

NdFeB, SmCo

Useful information

Neodymium and Samarium-Cobalt magnets are high energy permanent magnets and consist mainly of alloys of rare earth metals (neodymium, samarium) and other metals (e.g., iron, cobalt).

The most common shapes are square, disc, ring and segment magnets. However, other shapes can be made.

Like all sintered metals, rare-earth magnets, in particular SmCo magnets, are very hard and brittle and are therefore sensitive to impacts.

At low temperatures, SmCo magnets are relatively resistant to moisture, solvents and alkalis, but not to acids and salt solutions. NdFeB magnets corrode in moisture and react strongly to acids and salt solutions. By galvanic or other coatings, the magnets can be protected against corrosion.

Because of their high hardness a mechanical machining of sintered rare earth magnets is only possible with diamond tools.

Process flow

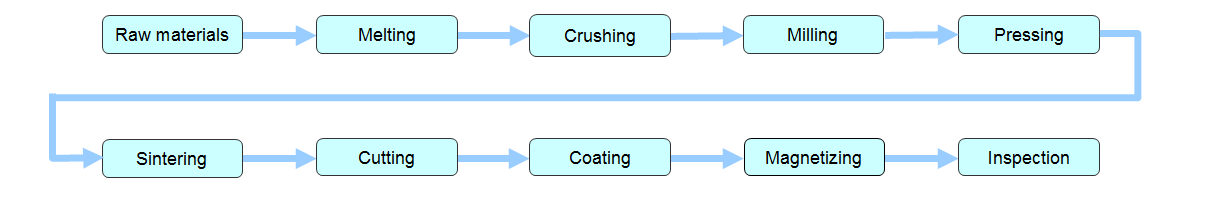

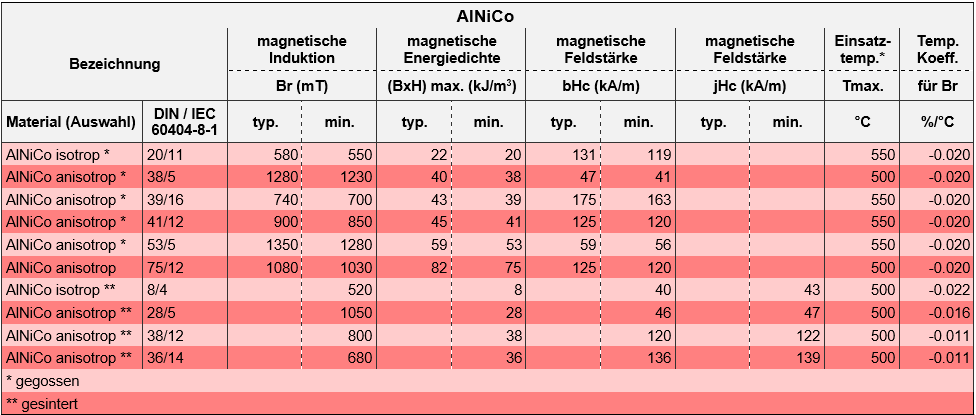

AINiCo

Useful information

AlNiCo magnets are metallic alloy magnets made of aluminum, nickel, cobalt, iron, copper, titanium and chromium.

They are produced by sand casting, chill casting, vacuum precision casting and sintering.

AlNiCo magnets are characterized by high remanences and small temperature coefficients and are therefore used where a constant magnetic field is required despite larger external temperature fluctuations. Compared to the new magnetic materials AlNiCo magnets have a low coercivity.

The high nickel content in the alloy results in a high resistance against most acids and against oxidation.

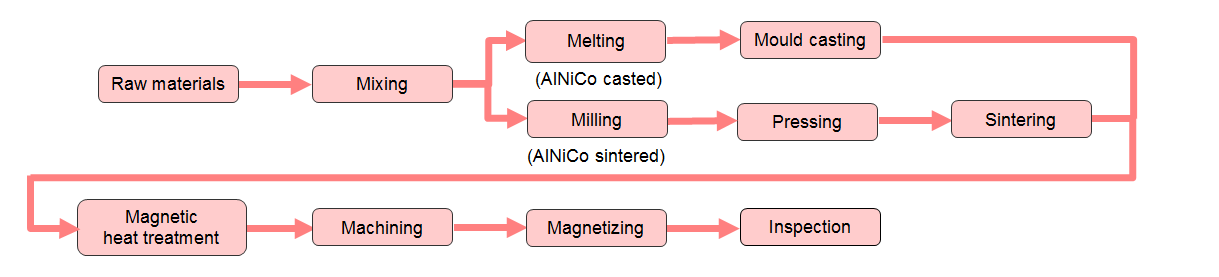

Process flow

HF

Useful information

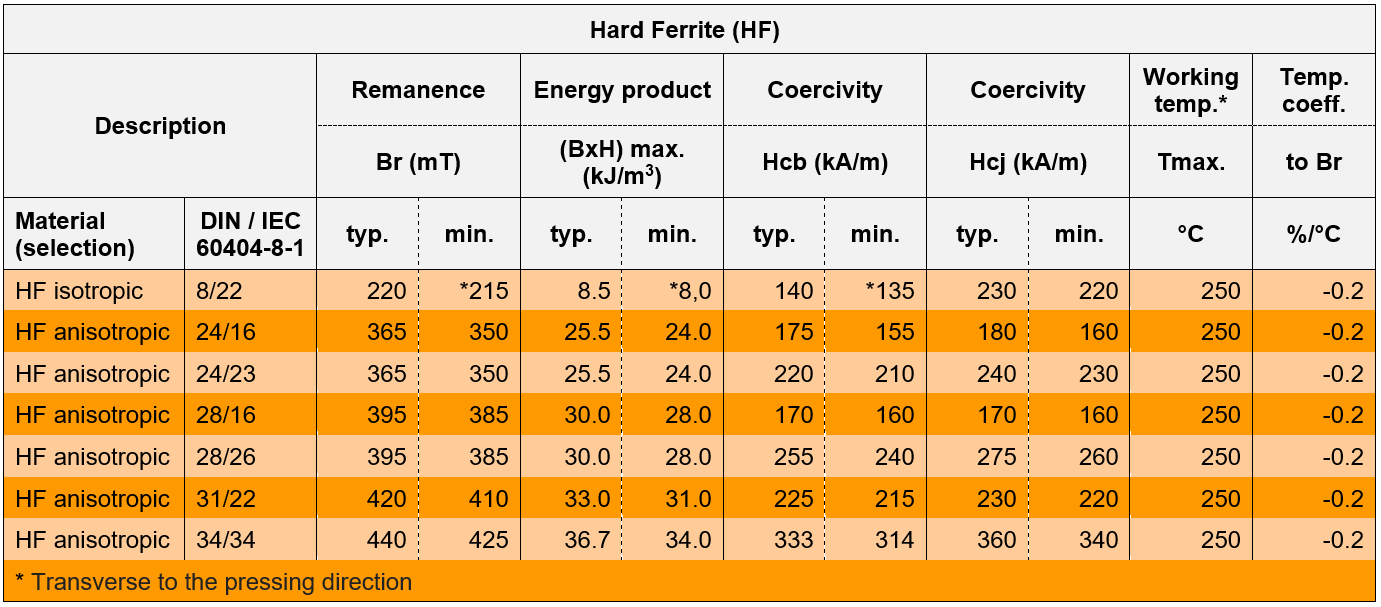

Hard ferrite magnets are the most economical and most widely used permanent magnets in the world. They consist of about 90% iron oxide and 10% barium or strontium oxide. They have excellent magnetic stability. The coercive force is high in relation to the remanence, which requires a large magnetic surface.

Hard ferrite magnets can be made isotropic or anisotropic. Isotropic magnets have approximately the same magnetic values in all directions and can be magnetized in all directions. Anisotropic magnets are exposed to a magnetic field during the pressing process and thereby obtain a preferred direction. They have good magnetic properties only in this preferred direction and can only be magnetized in this direction. Anisotropic magnets achieve significantly higher magnetic values than isotropic magnets.

Hard ferrite magnets behave mechanically like ceramic and porcelain, they are sensitive to impact and bending loads. Due to their ceramic character, hard ferrite magnets are resistant to weather influences and to many chemicals such as e.g. solvents, alkalis and weak acids.

Because of their great hardness hard ferrite magnets must be machined with diamond tools.

Changing temperatures cause a changed of the magnetic behavior in isotropic and anisotropic hard ferrite magnets. As the temperature increases, the remanence drops by 0.2% per 1°C and the coercivity increases by as much as 0.3% per 1°C. As the temperature decreases, the remanence increases and the coercive force drops to the same extent. As a result, magnets and magnet systems with a low operating point can suffer a permanent magnetization loss.

The surface of hard ferrite magnets can be varnished or flocked in various ways. A galvanic treatment is conditionally possible.

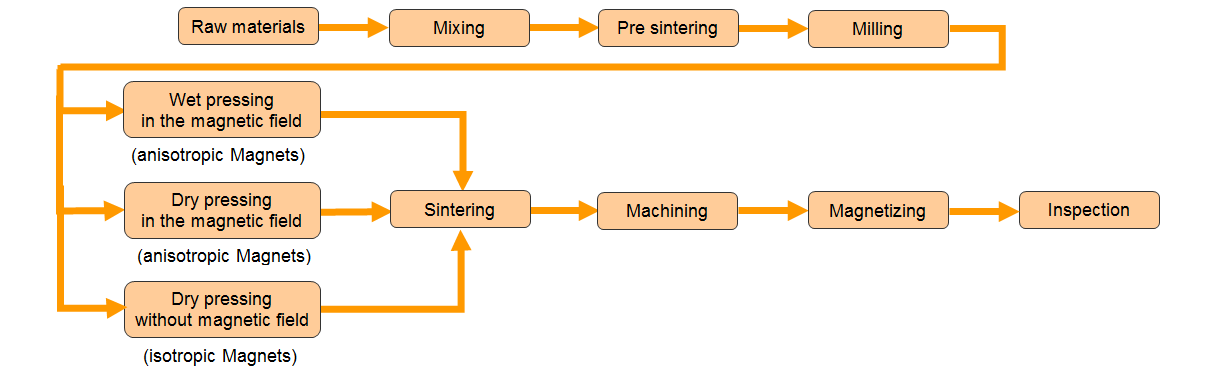

Process flow

Plastic Bonded Magnets

Useful information

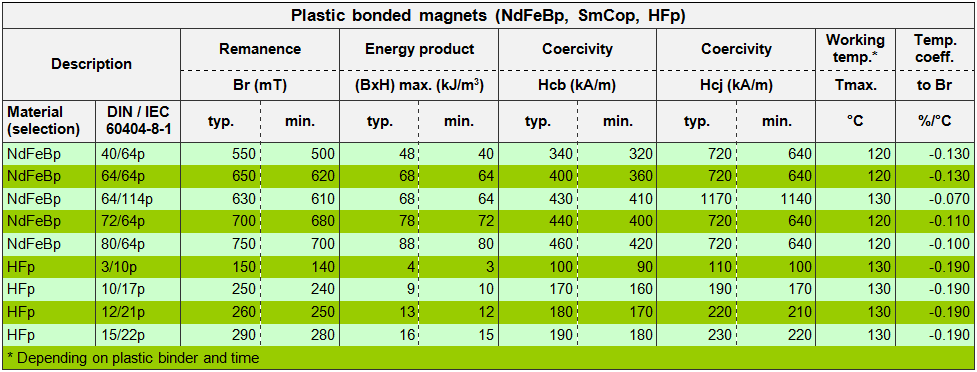

In plastic bonded magnets, magnet powder made of Neodymium, Samarium Cobalt or Hard Ferrite is mixed with thermoplastics and injected into a mould, or pressed.

By applying magnetic fields in the tool, a preferred direction in the axial, radial or diametrical direction can be applied so that isotropic and anisotropic magnets are possible.

Although the magnetic values are not equal to those of the solid material, there are some advantages to this process.

One of the main advantage of plastic bonded magnets is the enormous variety of shapes. So pinion and other functional parts of the same material can be injected at the same time. Shafts or other components can be inserted by means of extrusion coating. It is also possible to press in shafts afterwards because of the close injection moulding tolerances and the material elasticity.

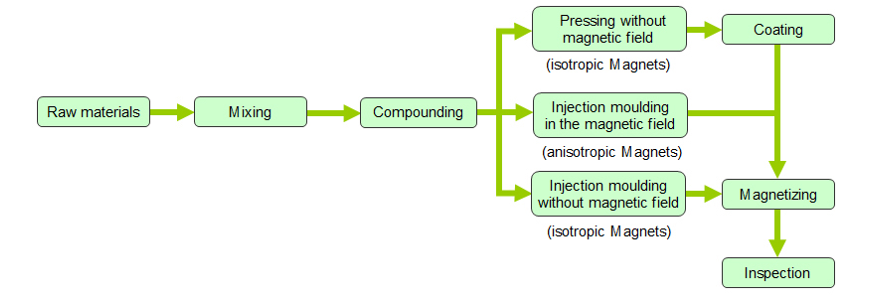

Process flow

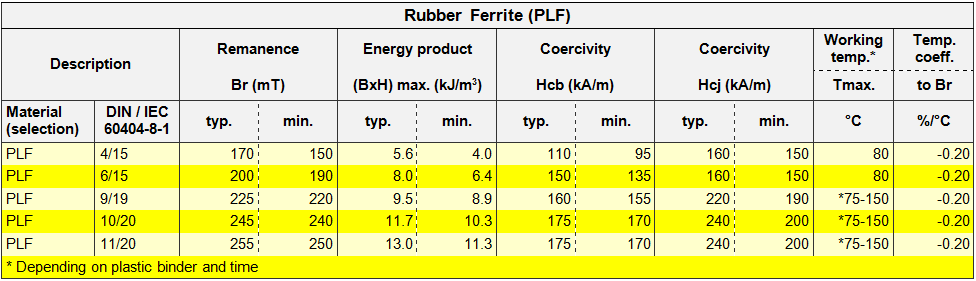

Rubber Ferrite (PLF)

Useful information

Rubber Ferrite (magnetic sheets) are made of hard ferrite powder and an elastic, thermoplastic binder and can be produced in the form of sheets and strips and as extruded profiles. As a binder, EPDM is generally used for thicknesses of 0.5 mm to 2 mm, and for thicknesses of 1 mm to 15 mm nitrile.

There are isotropic to anisotropic qualities, with anisotropic qualities having higher magnetic values. They can be magnetized on one or both sides multipolar or over the height. Through an iron backing plate (thickness at least 0.3 mm), the adhesive force can be significantly increased.

Rubber Ferrite is resistant to air, ozone, water vapor and weak acids / alkalis. The swelling or even the dissolution of the material may trigger by gasoline, mineral oil, acetone, benzene and chlorinated solvents. Rubber Ferrite bound with EPDM has a max. Operating temp. of 80°C, those with nitrile binder 100°C, in short term even 150°C.

There are different versions available:

- raw

- one-sided self-adhesive

- welded on one side with PVC film, colors white matt or high gloss, yellow, blue, green, red and black

The advantage of this material is the high flexibility, the rational production for large quantities and the ease of machining by punching, cutting with scissors, drilling, etc.

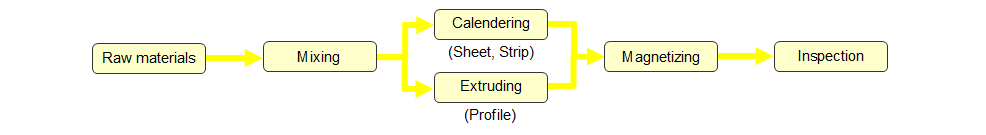

Process flow

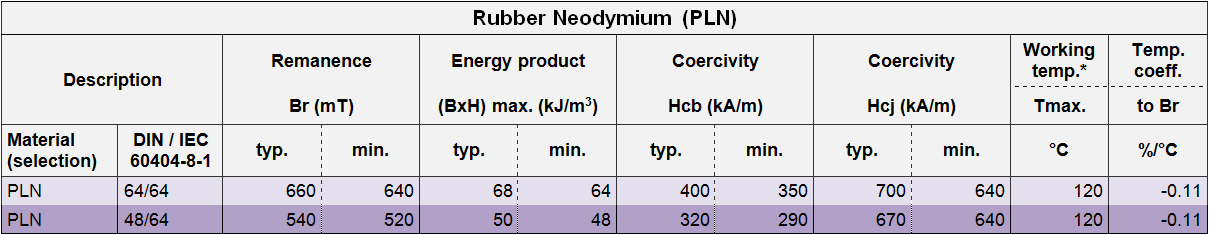

Rubber Neodymium (PLN)

Useful information

Rubber Neodymium (magnetic sheets and strips) consists of Neodymium powder and an elastic, thermoplastic binder and can be produced in the form of sheets and strips and extruded profiles.

Rubber Neodymium has about a 6 times higher adhesion and a 3 times higher flux density than Rubber Ferrite.

They can be magnetized on one or both sides multipolar or over the height. Through an iron backing plate (thickness at least 0.3 mm), the adhesive force can be significantly increased.

Rubber Neodymium are resistant to air, ozone, limited against water vapor and weak acids / alkalis. There are different versions available:

- raw

- one-sided self-adhesive

- welded on one side with PVC film, colors white matt or high gloss, yellow, blue, green, red and black

The advantage of this material is the high flexibility, the rational production for large quantities and the ease of machining by punching, cutting with scissors, drilling, etc.

Process flow