Wear-free torque transmission using eddy current technology

The eddy current coupling uses induced currents in a conductive material to transmit torque. It allows for contactless, wear-free power transmission and is particularly well suited for dynamic applications with frequent load changes – such as in conveyor systems, test benches, or drive systems with high demands on service life and maintenance-free operation.

We develop and manufacture couplings according to customer specifications.

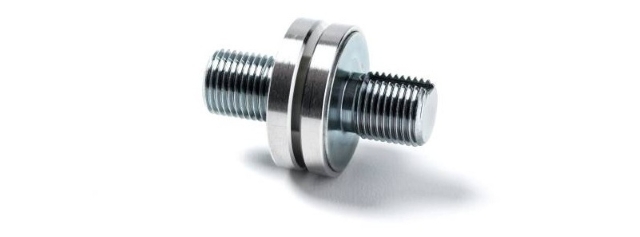

Eddy current coupling or brake

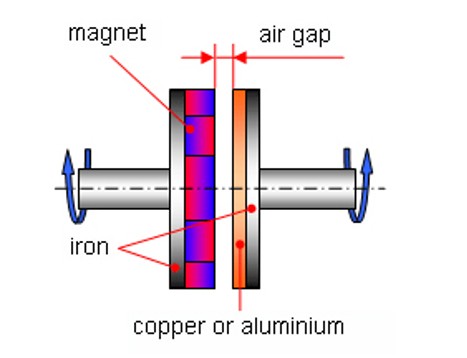

Schematic structure

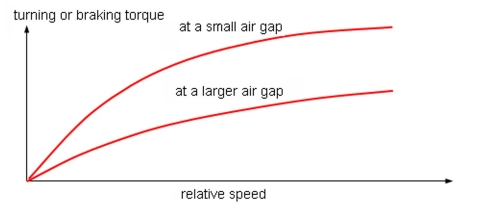

Technical information

For eddy current clutches or brakes, a multi-pole magnetized magnet faces an aluminum or copper disc which is connected to an iron disk of the same diameter. The turning or braking torque depends on the dimensioning, the magnetic material, the number of poles, the air gap and the relative speed. The higher the speed, the higher the transmitted turning or braking torque. If necessary the torque or brake moment can be slightly adjusted by axial displacement that means by changing the air gap. Since eddy-current couplings and brakes heat up strongly as speed increases due to the formation of eddy currents the values of the achievable turning or braking torque greatly decrease depending on the temperature reached

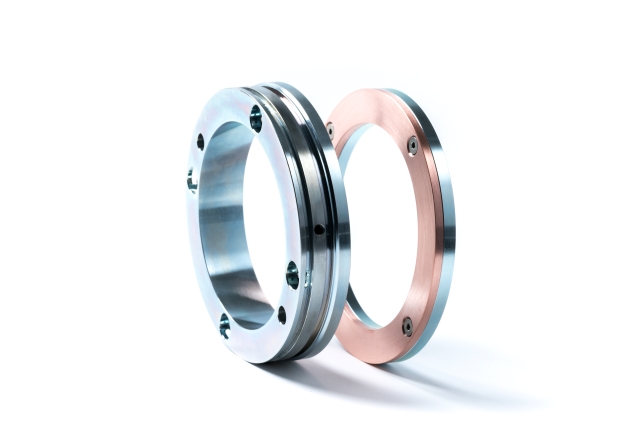

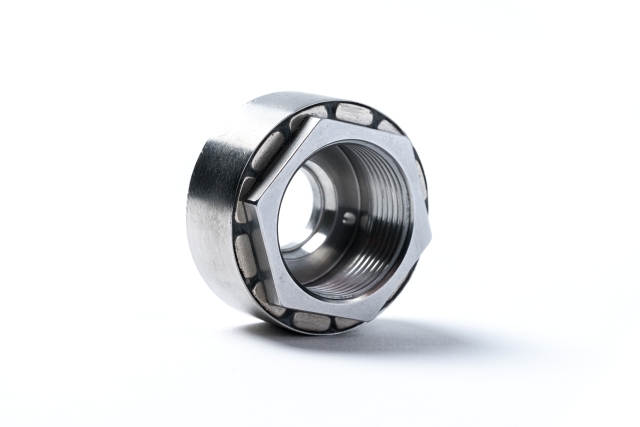

Customer examples

|

|